| Learning Aims: |

|

| Materials: |

|

| Suggestions for use and possible questions: |

|

Procedure:

Discussion:

Polyurethane (PUR) foams in a spray form can be one–component (prepolymer) or two-component (two monomers). In the polyaddition –NH– groups are formed, which can, in a smaller extent, convert into isocyanate groups. During this reaction, there occurs the initiation of these groups by water (air moisture), an intermediate product is formed – aryl carbamic acid, which leads to the elimination of carbon dioxide that will foam up the polyurethane. …–R=N=C=O + H2O → …–R–NH–COOH…→ …–R–NH2 + CO2↑(gas) isocyanate aryl carbamic acid amine The formed amine reacts with isocyanate (monomer or also a newly formed group) and a polyurethane polymer is formed. …–R=N=C=O + NH2–R–…→ …–R–NH–CO–NH–R–… PUR foams are used as insulation; their advantage is that they are waterproof but on the other hand they absorb air moisture, ensuring thus “breathing“ of the insulated structure. The reaction is initiated by water; the presence of water in the reaction mixture is therefore helpful for a full reaction throughout the entire volume and for a formation of quality reinforced polymer across the entire volume, which should be evident when the polymer was cut in half. Minimally the presence of water will fasten the reaction, i.e. the foam is formed in a shorter time. From the experiment it is also evident that the structure and consequently also the properties of polymer can be affected by the conditions of preparation, which will further broaden the structure of polymer properties.

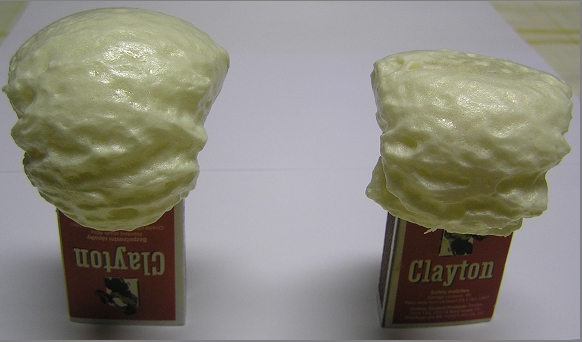

Prepared polyurethane foam, on the left PUR foam formed with a wetted box.

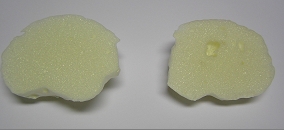

Cross section through PUR foam, on the left PUR foam formed with a wetted box. |